Precision Agriculture: Concepts and Opportunities for Montana Producers

Agriculture and Natural Resources

MT202502AG

New June 2025

By Ricardo Pinto, Dept of Research Centers, MSU Northern Agricultural Research Center; Anish Sapkota and Paul Nugent, Land Resources and Environment Sciences, MSU Bozeman; Sam Wyffels, MSU Dept of Animal and Range Sciences, MSU Extension Beef Cattle Specialist

Precision agriculture (PA) is transforming farming and ranching operations worldwide by enhancing productivity, efficiency, and sustainability. In Montana, with vast agricultural landscapes and diverse agricultural systems, PA offers promising opportunities to address unique challenges and optimize operations. This guide will provide an overview of PA, practical steps for implementation, and insights tailored to Montana’s agricultural community.

Core insights

- Enhanced agricultural efficiency: Precision agriculture can improve efficiency and sustainability in Montana’s diverse agricultural systems.

- Resource optimization: Resources such as yield and vegetation index maps, variable-rate technology, and virtual fencing can reduce input costs, improve resource allocation, and optimize livestock management.

- Implementation opportunities: We provided examples of how to use PA to optimize nitrogen, manage soil acidification, and implement targeted grazing strategies to boost productivity and profitability.

- Adoption guidance: Successful PA implementation requires clear goals, suitable technologies, integration with current practices, and gradual scaling from small pilot projects.

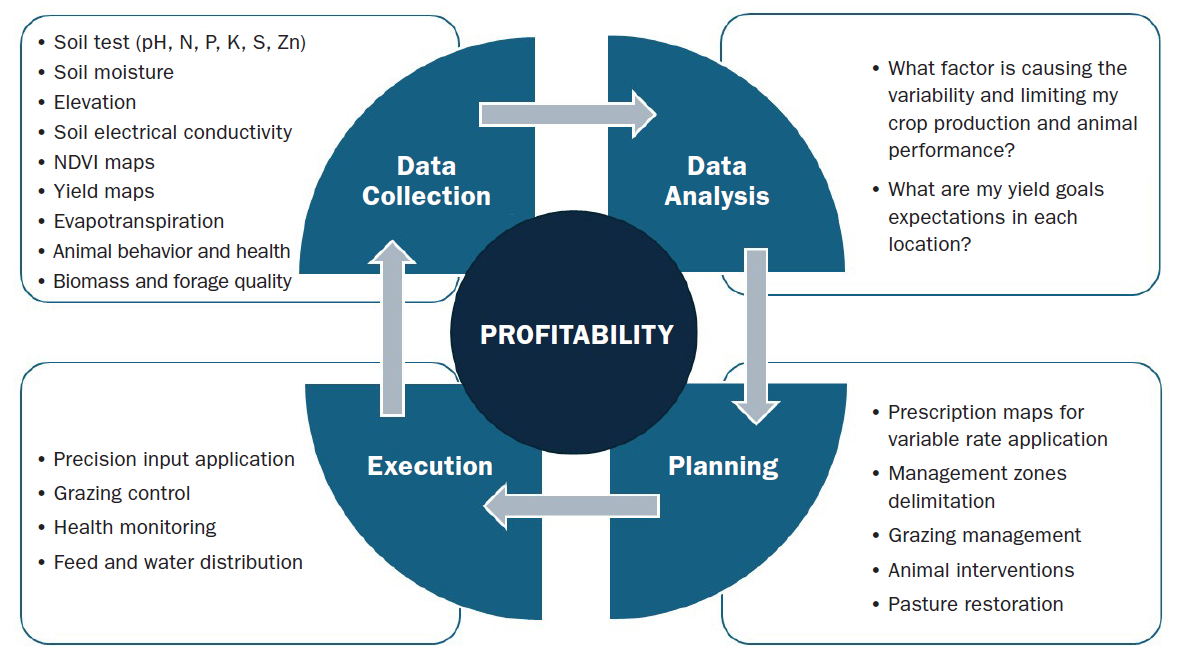

- Precision workflow: A stepwise approach to data collection, analysis, planning, execution, and profitability evaluation ensures informed decisions and measurable outcomes.

What is precision agriculture?

Precision agriculture uses practices that account for the spatial and temporal variability (soil properties, crop health, weather patterns, etc) in agricultural fields, livestock pastures, and intra-animal variation in livestock (e.g. body temperature, activity level, rumen pH). While PA is often associated with modern tools like unmanned aerial systems (UAS; also known as drones), sensors, and Global Positioning System (GPS) equipment, precision agriculture is not new.

The principles of adapting farming practices to account for variability within fields have been practiced for decades. It dates to the 1970s with the advent of grid soil sampling to determine fertilizer rates across a field. The potential for broad adoption of precision agriculture has increased dramatically due to a confluence of factors. The widespread availability and decreasing costs of GPS sensors make them more accessible to producers. Computer technological advancements, coupled with increasing computer and technological literacy, have reduced reliance on specialized expertise. At the same time, farms are facing high input costs in fertilizers, pesticides, and equipment, and high uncertainty with weather patterns that increasingly diverge from historical norms, creating both economic and environmental needs for precision agriculture. Together, these forces are accelerating PA integration into modern farming systems.

In Montana, precision agriculture research began in the late 1980s, led by Gerald A. Nielsen, Dan Long, Pat Carr and a few others. Their work demonstrated the importance of addressing soil variability to optimize fertilizer use (Carr et al. 1991), evaluated the cost-effectiveness of variable rate nitrogen fertilization (Long et al. 1996), and explored methods for delineating nitrogen management zones (Long et al. 2000). These studies provided foundational insight into how precision management practices could improve nitrogen use efficiency and profitability in the state’s northern grain-growing regions. Today, producers have access to even more advanced tools and techniques, making precision agriculture a practical and valuable approach for optimizing resources, increasing yields, and enhancing sustainability.

What is the objective of precision agriculture?

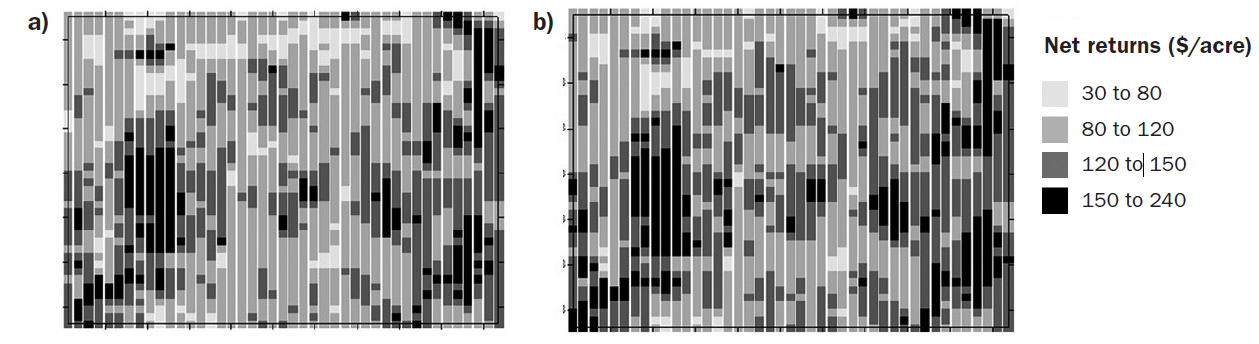

Traditional whole-field management treats a field as uniform, applying a single rate of inputs. This approach often results in under-fertilizing highly productive areas and over-fertilizing less productive areas due to field variability, or wasting money on pesticides that are only needed in some areas. Today’s precision agriculture technologies allow producers to manage inputs more effectively, focusing on what each part of a field truly needs. This shift can make a significant difference in profitability and sustainability by increasing yields with the same input levels that are distributed more effectively. Targeting inputs precisely where needed improves crop quality by tailoring practices to specific field conditions. For instance, a multi-year study conducted near Sun River demonstrated the potential of site-specific (SS) nitrogen management to improve profitability and input efficiency in dryland wheat production (Figure 1). Researchers collected data from three fields over seven crop years, using SS measurements of wheat yield, protein content, nitrogen application rates, weed density, soil electrical conductivity, and topographic characteristics. They found that SS nitrogen management increased net returns by an average of $21.70 per acre, with some fields seeing gains as high as $86.90 per acre. Across the study, nitrogen application was optimized to better match spatial variability within fields, resulting in an average nitrogen savings of 36 pounds per acre. Importantly, recommended nitrogen rates varied substantially from traditional uniform applications, in some areas suggesting up to 76 pounds more nitrogen per acre, while others recommended reductions of up to 170 pounds per acre. These findings highlight the value of SS technologies in tailoring nitrogen inputs to field-specific needs, ultimately enhancing nitrogen use efficiency, increasing profitability, and minimizing environmental risk.

Precision agriculture also offers significant benefits for livestock operations. Traditional livestock management often involves broad, one-size-fits-all practices, such as rotating grazing across entire pastures without regard for specific pasture conditions. However, precision livestock management technologies enable producers to optimize grazing patterns, monitor animal health, and manage forage resources more effectively. They allow producers to make data-driven decisions to improve the overall productivity and sustainability of their operations.

Why use precision agriculture in Montana?

Agricultural systems are naturally complex, with challenges such as unpredictable weather, soil variability, input costs, and rapidly shifting pest pressures. Precision agriculture offers innovative tools to address these challenges efficiently and effectively. For instance, soil acidification, a growing concern in Montana, can be identified using remote sensing technologies (Webb et al. 2021). Remote sensing enables producers to pinpoint affected areas early, allowing for accurate diagnoses and timely interventions to prevent widespread damage and economic loss.

Precision agriculture significantly enhances resource optimization and labor efficiency. Technologies such as satellite and drone imagery, electromagnetic conductivity, and gamma-ray sensors enable producers to understand field variability and focus management efforts on specific locations. This targeted approach saves time and ensures that inputs are applied precisely where needed.

Figure 1. Distribution of net returns ($/acre) near Sun River, Montana, a) with the farmer’s N rate and b) with the optimized SS N rate application (Barroso, et al. 2013).

Examples in cropping systems

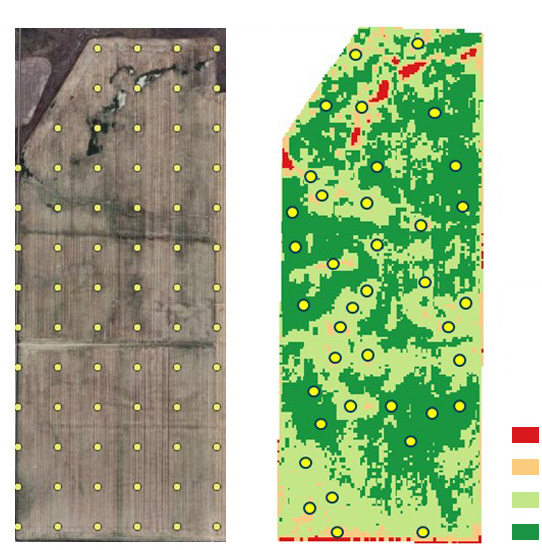

Vegetation indices like the Enhanced Vegetation Index (EVI), measure the greenness (chlorophyll), vigor, and health of crops. These indices can improve soil sampling strategies. Using freely available, historical, satellite-acquired EVI images from Landsat or Sentinel 2, producers can use variability in biomass and chlorophyll content to guide soil sampling. This results in a reduced number of soil samples while maintaining diagnostic precision compared to traditional grid sampling. For instance, using four seasons of historical data EVI-guided sampling in a 363 acre field located near Teton County can reduce soil sampling points from 76 (using grid sampling) to 38, significantly cutting costs and preserving efficiency (Figure 2). Moreover, reducing sample collection reduces labor and laboratory analysis costs, as the zone method, where fields are divided into management zones based on similar soil or yield characteristics, allows soils from the same zone to be mixed and analyzed together.

Figure 2. Traditional grid sampling compared to remote-sensing-guided sampling based on Enhanced Vegetation Index (EVI) in a 363 acre field in Montana. Each yellow point represents a soil sample location (Pinto et al. 2025, unpublished data).

Another transformative precision agriculture innovation is precise herbicide management tools. Methods involve using nozzle control systems to apply herbicides only where weeds are found, significantly reducing chemical usage. Precision spraying technologies like WEED-IT (WEED-IT Quadro, Rometron, Netherlands), See and Spray (John Deere, USA), Carbon Bee (Carbon Bee AgTech, France), and WeedSeeker (WeedSeeker 2, Trimble, USA) offer substantial benefits. Field trials near Huntley (Sharma et al. 2023), demonstrated that WeedSeeker utilization in fallow fields could reduce overall chemical use by 23-55 percent leading to cost savings of $2.36 to $12.45 per acre across various herbicide treatments, all while maintaining effective weed control. Considering the 363 acre field in Teton County, these savings would range from $858 to $4,521, highlighting a significant reduction in herbicide costs. When scaled to the average 2,039 acre dryland farm in Montana’s Golden Triangle region, this translates to savings ranging from $4,813 to $25,371, offering substantial financial benefits while enhancing environmental sustainability and maintaining effective weed control in chemical fallow situations.

Precision agriculture enables producers to explore and maximize their land’s productivity potential. By considering unique soil and climate conditions, producers can set realistic yield goals and implement targeted practices to achieve them. Improved variety management is another major advantage. Precision data allows producers to strategically position specific crop varieties in areas where they are most likely to thrive. For example, in Montana, adopting solid-stemmed wheat varieties with higher tolerance to wheat stem sawfly (WSS), an economically significant pest, is a crucial strategy. Targeting varieties to areas of high pest infestation can help producers make informed decisions about adopting solid-stemmed cultivars, planting rotational crops, or even swathing (recovering wheat heads lodged by large WSS infestations) specific wheat fields.

Examples in livestock production

Virtual fencing technology offers a flexible, cost-effective solution for controlling livestock movement without relying on physical barriers. Using GPS-equipped collars, producers can precisely manage grazing in rangeland and cropland systems. This technology allows for short-term grazing of cover crops or crop residues without the time and labor required with temporary fences. Virtual fencing can also optimize grazing distribution within pastures, reducing labor costs, improving forage utilization, and enhancing the profitability of livestock operations.

Other sensor technology in livestock production has advanced significantly, enhancing animal health, productivity, and management efficiency. Activity monitors (accelerometers) are used in wearable devices such as collars and ear tag sensors to provide real-time monitoring of animal activity, detecting behaviors like estrous, calving, grazing, resting, or signs of illness. GPS ear tags provide real-time location tracking, enabling precision grazing management and reducing the risk of missing animals. Other non-wearable technologies have the potential to significantly enhance livestock management, including water monitoring systems, automated feeders, and drones. Water monitoring systems ensure livestock have constant access by measuring and monitoring livestock water availability and system function, alerting producers when a problem occurs. Automated feed systems optimize nutrition by delivering precise feed amounts based on individual animal needs, reducing waste, and improving growth performance and management. Drones equipped with thermal imaging and high-resolution cameras assist in livestock monitoring by providing aerial surveillance, tracking herd movements, locating stray animals, and assessing pasture conditions. Together, these technologies contribute to more sustainable and data-driven livestock management, improving animal welfare and operational efficiency.

How to get started with precision agriculture

Transitioning from traditional whole-field or whole-herd management to site-specific practices requires careful planning and clear goal setting. Before adopting precision agriculture, producers should consider their objectives, available resources, and desired outcomes.

- Define goals: Start by asking what can be achieved with precision agriculture. Whether it’s improving yield, reducing input costs, maximizing profit, or optimizing resource use, setting specific goals will guide decisions and actions.

- Establish timeline expectations: Different practices have different timelines for return on investment. For example, auto-steering, spot spraying herbicide, and livestock tracking have immediate in-season benefits upon system startup. Other techniques, like variable rate fertilizer and optimized grazing, may take multiple seasons before benefits are obtained consistently.

- Choose the right technologies: Once the goals and timeline are clear, assess which technologies are best suited and which are required to achieve the goals. For example, to avoid running over plants during row-crop operations, investing in auto-steer systems can be a solution, but this also requires a high-precision GPS such as RTK-GPS. If its unclear where improvements can be made but data has been collected (e.g., from a yield monitor), working with an agronomist, Extension agent or using mapping software can help generate and interpret yield maps or vegetation index maps. Variable-Rate Technology could address these issues by applying inputs more precisely.

- Integrate with current practices: Think about how to integrate new technologies and practices into an existing system. Consider how each tool or practice will fit with what’s already being done and how it can enhance operational efficiency.

- Establish an appropriate implementation plan: Practices and technologies require different implementation strategies. For example, a green-on-brown spot spray system, which uses sensors to detect and target green plant material against a non-vegetated background such as bare soil or crop residue, would likely be implemented across most, if not all, fallow ground in the first year. Otherwise, a sufficient return on investment couldn’t be gained. Other technologies, like Variable-Rate nitrogen, will have reduced risk if it’s begun with a small pilot project on a specific field or crop. This allows for adapting and refining practices before scaling them up to larger areas.

- Monitor and evaluate: Once PA practices are implemented, regularly monitor performance. Track the impact on yields, resource use efficiency, and overall profitability. This will help make more informed decisions, adjusting the approach as needed, and optimizing the benefits of precision agriculture.

Once clear objectives are established, following the PA workflow (Figure 3) is essential to successfully implement goals. The first step is to collect the data to understand variability. In crop operations, this involves gathering data on crop health, soil conditions, and environmental factors using technologies like satellite imagery, yield monitors, soil sampling, and weather stations. For livestock operations, it may include tracking livestock movement with GPS collars or ear tags, monitoring health parameters like weight or activity levels, and assessing pasture conditions with sensors.

Figure 3. Precision agriculture implementation workflow.

The next step is to process the data. This stage involves analyzing the collected information to identify patterns and insights. For example, in crop farming, soil data can be processed to create fertilizer prescription maps, while in livestock operations, GPS and health data can be used to map grazing patterns and detect animals that may need intervention.

The third step, planning, is where data-driven decisions are made. In crop production, this could mean dividing fields into management zones based on variability, allowing for targeted inputs like fertilizer or irrigation. In livestock management, it could involve planning grazing rotations or optimizing pasture usage.

Next, execution involves putting plans into action. In crops, this includes applying fertilizers, pesticides, and irrigation based on variable rates determined by the data, while in livestock operations, it means controlling grazing with virtual fencing, monitoring health through wearable sensors, and managing feed distribution. Central to this process is profitability. After the growing or grazing cycle, it is crucial to evaluate the return on investment (ROI) for each zone or area of the operation. By analyzing outcomes and comparing them with the initial inputs, a profitability map can be created. In crop farming, this map could highlight areas where inputs such as fertilizers, water, or labor were most effectively utilized, while identifying areas that consistently lose money, and could possibly be taken out of production (especially if on a field edge or saline area). For livestock operations, this step can help identify the best results in terms of animal weight gain or health improvement per animal, and identify underutilized areas of a pasture. This step ensures that investments are directed efficiently in future cycles, maximizing profitability and sustainability in both crop and livestock operations. This process leads back to the next production season, with knowledge of what was done and how the agricultural system responded, informing the cycle as it starts again with data collection.

Next steps in precision agriculture

This and future publications focused on PA are part of a targeted effort to expand the use of advanced agricultural technologies that will benefit Montana agriculture. This effort has two foundations: the first is the work on Montana’s farms and ranches initiated by Montana producers as they start adopting these technologies. The second foundation is the academic and Extension programs at Montana State University that support this transition. Understanding which technologies bring efficiency and economic gains to Montana agriculture will occur at the confluence of these efforts.

Academic efforts have started at MSU with the establishment of a cross-disciplinary PA minor degree program. This program is planned to grow into a reimagined Agriculture Engineering program built around PA and value-added processes. Publications related to this program may document information and practices gained, as well as PA adoption and current barriers to adoption in Montana.

References

Barroso, J., Lawrence, P., Merja, C., & Maxwell, B. (2013). Spatial Optimization of Nitrogen Application for Wheat. https://landresources.montana.edu/fertilizerfacts/documents/FF65SiteSpecificNFertWheat.pdf

Carr, P. M., Carlson, G. R., Jacobsen, J. S., Nielsen, G. A., & Skogley, E. O. (1991). Farming soils, not fields: A strategy for increasing fertilizer profitability. Journal of Production Agriculture, 4(1), 57-61. https://acsess.onlinelibrary.wiley.com/doi/full/10.2134/jpa1991.0057

Long, D. S., Carlson, G. R., & Nielsen, G. A. (1996, January). Cost analysis of variable rate application of nitrogen and phosphorus for wheat production in northern Montana. In Proceedings of the Third International Conference on Precision Agriculture (pp. 1019-1031). Madison, WI, USA: American Society of Agronomy, Crop Science Society of America, Soil Science Society of America. https://doi.org/10.2134/1996.precisionagproc3.c125

Long, D. S., Engel, R. E., & Carlson, G. R. (2000). Method for precision nitrogen management in spring wheat: II. Implementation. Precision Agriculture, 2, 25-38. https://doi.org/10.1023/A:1009980432643

Sharma, P., Kumar, V., & Jha, P. (2023). Efficacy and economics of light‐activated sensor‐controlled sprayer for site‐specific weed control. Agronomy Journal, 115(5),2590-2599. https://doi.org/10.1002/agj2.21420

Webb, H., Barnes, N., Powell, S., & Jones, C. (2021). Does drone remote sensing accurately estimate soil pH in a spring wheat field in southwest Montana? Precision Agriculture, 22(6), 1803-1815. https://link.springer.com/article/10.1007/s11119-021-09812-z

Additional resources

Andrade-Sanchez, P., & Heun, J. T. (2010). Understanding technical terms and acronyms used in Precision Agriculture. https://extension.arizona.edu/sites/extension.arizona.edu/files/pubs/az1534.pdf

Rains, G. C., & Thomas, D. L. (2009). Precision farming: An introduction. University of Georgia. https://openscholar.uga.edu/record/25068?v=pdf

Acknowledgments

We thank the Montana Agriculture Experimental Station for supporting the authors’ studies. We also thank collaborating producers for providing data and allowing research to be conducted on their farms.

Disclaimer

Commercial products, tools, and services presented in MontGuides are for reference only. MSU does not endorse or recommend specific products and/or programs.

To download more free online MontGuides or order other publications, visit our online catalog at store.msuextension.org, contact your county or reservation MSU Extension office, or e-mail [email protected].

Copyright © 2025 MSU Extension

We encourage the use of this document for nonprofit educational purposes. This document

may be reprinted for nonprofit educational purposes if no endorsement of a commercial

product, service or company is stated or implied, and if appropriate credit is given

to the author and MSU Extension. To use these documents in electronic formats, permission

must be sought from the Extension Communications Director, 135 Culbertson Hall, Montana

State University, Bozeman, MT 59717; E-mail: [email protected]

The U.S. Department of Agriculture (USDA), Montana State University and Montana State University Extension prohibit discrimination in all of their programs and activities on the basis of race, color, national origin, gender, religion, age, disability, political beliefs, sexual orientation, and marital and family status. Issued in furtherance of cooperative extension work in agriculture and home economics, acts of May 8 and June 30, 1914, in cooperation with the U.S. Department of Agriculture, Cody Stone, Director of Extension, Montana State University, Bozeman, MT 59717.