Housing Honey Bees

Ruth O’Neill, Research Associate

Wanner Crop Entomology Lab, Plant Sciences and Plant Pathology

Honey bees require snug dry housing that is insulated from weather extremes, protected from predators, and provided with plenty of room for rearing brood and storing honey.

Most beekeepers, whether they are commercial producers or hobbyists, house their bees

in a “Langstroth hive”. Many bee supply businesses carry them as kits, usually costing

around $120.00 for basic components, not including shipping. Other hive styles can

be made from kits or DIY instructions available on the web or in some beekeeping books.

Some of these alternative set-ups are shown at the end of this page.

Most beekeepers, whether they are commercial producers or hobbyists, house their bees

in a “Langstroth hive”. Many bee supply businesses carry them as kits, usually costing

around $120.00 for basic components, not including shipping. Other hive styles can

be made from kits or DIY instructions available on the web or in some beekeeping books.

Some of these alternative set-ups are shown at the end of this page.

Langstroth hive:

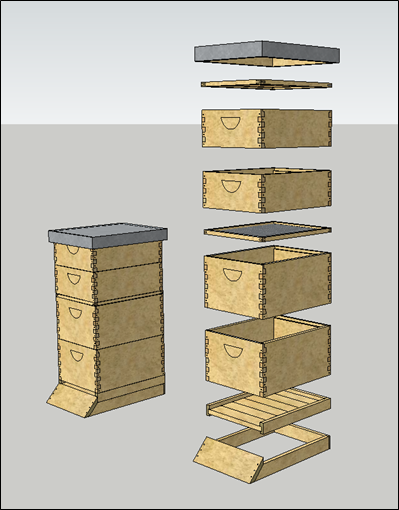

The figure to the right shows a standard ten-frame Langstroth hive with the most basic hive components. Langstroth hive components are stacked vertically. No fasteners are required to join the components to one another because the bees fasten the seams together with propolis, a sealant made from a mixture of plant resins (from various sources) mixed with beeswax. However, a strap can be helpful to protect the hive from being knocked over by wind or large animals.

From bottom to top, the components shown in the top right figure are discussed below:

Hive stand: The function of the hive stand is to raise the hive off the ground, usually

two to twelve inches, to keep the colony dry. You can buy hive stands (shown), but

you can also improvise with whatever you have on hand. For example, concrete blocks,

scrap wood, or wood pallets work well. Situate the hive stand so that the hive tilts

slightly forward, to prevent moisture from collecting on the floor.

Hive stand: The function of the hive stand is to raise the hive off the ground, usually

two to twelve inches, to keep the colony dry. You can buy hive stands (shown), but

you can also improvise with whatever you have on hand. For example, concrete blocks,

scrap wood, or wood pallets work well. Situate the hive stand so that the hive tilts

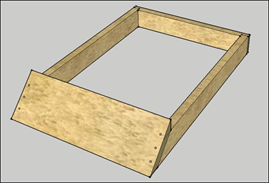

slightly forward, to prevent moisture from collecting on the floor. Bottom board: This is the floor of the hive. Three sides are raised about ¼” so

that when the main brood box is in place above the hive entrance is formed. Traditional

bottom boards are solid wood, but you can also buy screened bottom boards. Some bottom

boards have a removable solid tray fitted into a screened bottom board, giving the

beekeeper the ability to clean the floor of the hive out, place sticky pest traps

inside, or leave the drawer out during the summer to expose the screened floor.

Bottom board: This is the floor of the hive. Three sides are raised about ¼” so

that when the main brood box is in place above the hive entrance is formed. Traditional

bottom boards are solid wood, but you can also buy screened bottom boards. Some bottom

boards have a removable solid tray fitted into a screened bottom board, giving the

beekeeper the ability to clean the floor of the hive out, place sticky pest traps

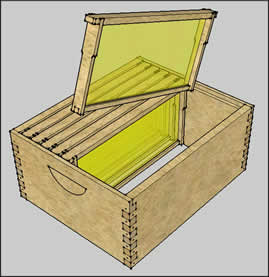

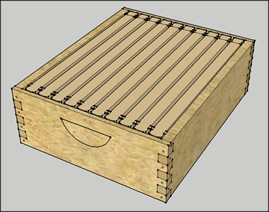

inside, or leave the drawer out during the summer to expose the screened floor. Brood boxes: These chambers house the queen and the developing bee brood. Each box

holds ten “deep frames” (six shown here), and each frame holds a sheet of “foundation”,

traditionally made of beeswax supported by fine wires. Foundation is stamped with

hexagonal imprints that guide bees in building comb. Most of the brood is clustered

in the center frames, with nectar, pollen, and honey stored in peripheral cells.

When bee packages are first introduced to an empty hive, one brood box is used. The

second brood box (also filled with frames) is added several weeks later, to give the

colony room to expand as summer progresses.

Brood boxes: These chambers house the queen and the developing bee brood. Each box

holds ten “deep frames” (six shown here), and each frame holds a sheet of “foundation”,

traditionally made of beeswax supported by fine wires. Foundation is stamped with

hexagonal imprints that guide bees in building comb. Most of the brood is clustered

in the center frames, with nectar, pollen, and honey stored in peripheral cells.

When bee packages are first introduced to an empty hive, one brood box is used. The

second brood box (also filled with frames) is added several weeks later, to give the

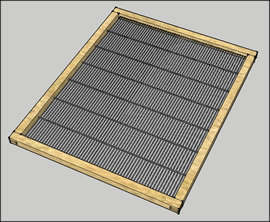

colony room to expand as summer progresses.  Queen excluder: This component keeps the queen from laying eggs in the honey supers

that will be placed above it. The gaps between the metal bars are five millimeters

wide, too narrow for the queen’s abdomen to fit through. Workers slip through the

bars and fill the empty cells with clean honey.

Queen excluder: This component keeps the queen from laying eggs in the honey supers

that will be placed above it. The gaps between the metal bars are five millimeters

wide, too narrow for the queen’s abdomen to fit through. Workers slip through the

bars and fill the empty cells with clean honey. Honey supers: Like the brood boxes, each honey super holds ten frames. Honey supers

are identical to brood boxes except that they are shorter. The smaller size makes

them easier to lift when they are full of honey. The super shown here is a “medium

super”, which when full can weigh 50 pounds. Even shorter “shallow supers” are also

available. Multiple supers can be added as needed during the summer to give bees more

room to store honey.

Honey supers: Like the brood boxes, each honey super holds ten frames. Honey supers

are identical to brood boxes except that they are shorter. The smaller size makes

them easier to lift when they are full of honey. The super shown here is a “medium

super”, which when full can weigh 50 pounds. Even shorter “shallow supers” are also

available. Multiple supers can be added as needed during the summer to give bees more

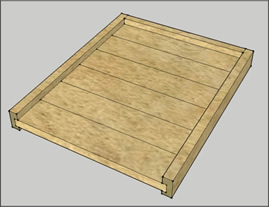

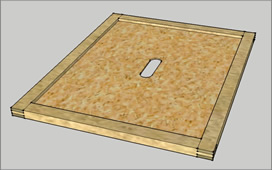

room to store honey. Inner cover: This is a sheet of framed Masonite with a slot in the middle that fits

certain types of syrup feeders. The inner cover provides extra insulation and moisture

protection in cold weather. It also keeps the bees from gluing down the telescoping

outer cover with propolis. Otherwise, the awkward overhang on the outer cover would

make it very difficult to pry off.

Inner cover: This is a sheet of framed Masonite with a slot in the middle that fits

certain types of syrup feeders. The inner cover provides extra insulation and moisture

protection in cold weather. It also keeps the bees from gluing down the telescoping

outer cover with propolis. Otherwise, the awkward overhang on the outer cover would

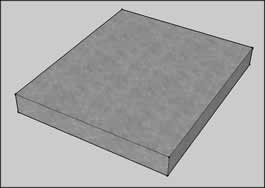

make it very difficult to pry off.  Telescoping cover: This top cover is a box with short overhanging sides that provides

weather protection. It is covered with galvanized sheet metal for moisture-proofing.

Telescoping cover: This top cover is a box with short overhanging sides that provides

weather protection. It is covered with galvanized sheet metal for moisture-proofing.

Some other hive styles:

WBC hives have internal boxes covered with an external housing. The double-walled construction

offers insulation from temperature extremes.

WBC hives have internal boxes covered with an external housing. The double-walled construction

offers insulation from temperature extremes.

Image: http://www.countryactivities.co.uk/beehives/wbchive.htm

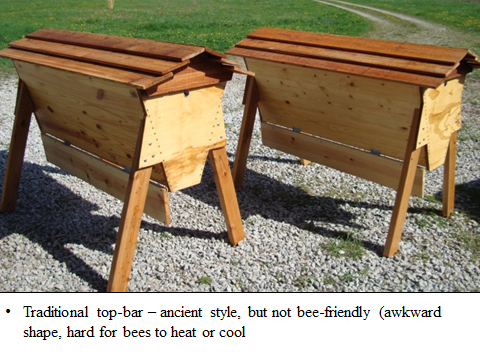

Top bar hives are oriented horizontally. Instead of holding full frames with foundation, like Langstroth

hives, they hold bars that rest along rails or dados along the inner top edge of the

hive body. Bees draw comb down from the top bars. At honey harvest, the beeswax

comb is harvested as well (it can’t be reused, as it can with Langstroth hives).

Top bar hives are oriented horizontally. Instead of holding full frames with foundation, like Langstroth

hives, they hold bars that rest along rails or dados along the inner top edge of the

hive body. Bees draw comb down from the top bars. At honey harvest, the beeswax

comb is harvested as well (it can’t be reused, as it can with Langstroth hives).

Image: http://beetherapy.org/blog/warre-langstroth-or-top-bar-which-hive-to-choose

Warré hives are vertically stacked, like Langstroth hives. The uppermost box contains insulation

(such as wool, foam, polyfill, or leaves). The remaining boxes contain top bars,

as in the top bar hives.

Warré hives are vertically stacked, like Langstroth hives. The uppermost box contains insulation

(such as wool, foam, polyfill, or leaves). The remaining boxes contain top bars,

as in the top bar hives.

Image: http://thebeespace.net/warre-hive