Deformable Membrane Focus Control Mirrors

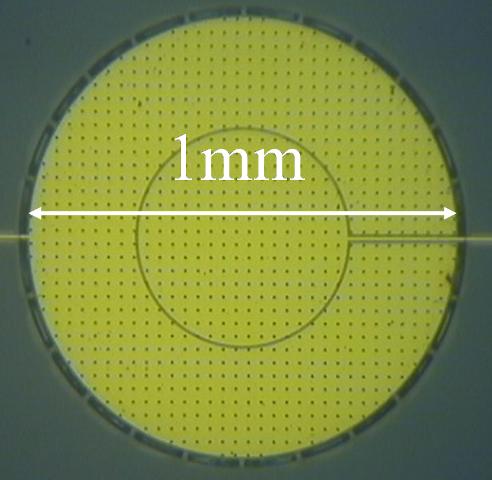

A 1 mm diameter silicon nitride membrane with two-zone electrostatic actuation can deflect several micrometers, with a mechanical bandwidth of 10s of kHz to more than 100 kHz (Himmer, 2001).

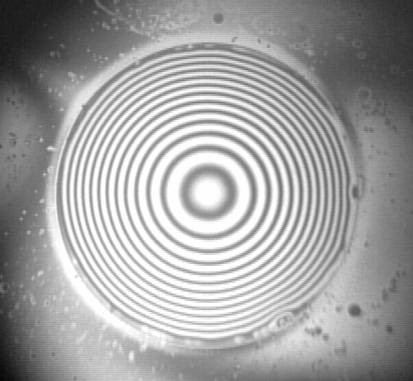

Polymer membranes made of SU-8 negative photoresist and coated with aluminum are capable of greater deflection than the stiffer silicon nitride material, but they are slower, with a bandwidth of several hundred Hz to a few kHz. This one is imaged under an interferometer to show the surface profile when a voltage is applied. Each contour represents a height step of 317 nm (Dunbar, 2008).

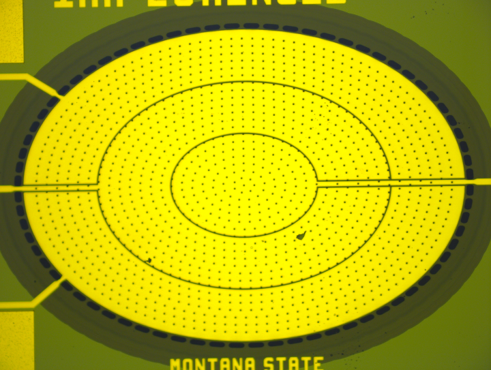

Surface micromachined SU-8 mirrors can achieve very high image quality (low initial aberration) with a simple fabrication process. With four or more concentric electrodes, these mirrors can control secondary and tertiary spherical aberration(Lukes, 2010). An elliptical shape is ideal for a beam incident at an angle to the surface normal.

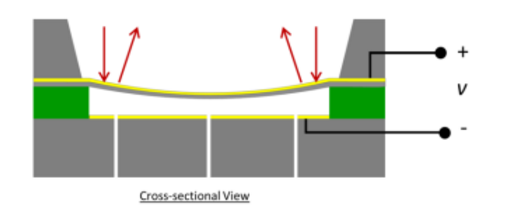

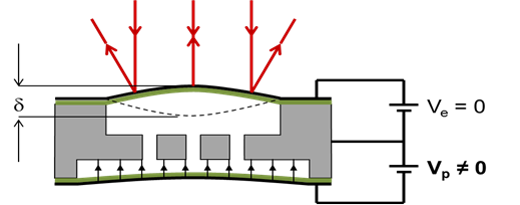

SU-8 membrane mirrors with electrodes hidden underneath are made using a wafer bonding process. Holes in the substrate under the membrane allow air flow to reduce damping and allow actuation bandwidths of 10s of KHz. (Moghimi, 2013).

Bonding three wafers together offers the possibility of two electrostatically operated membranes opposed to one another. Deflecting one toward the substrate causes the other one to bulge due to increased pressure in the sealed cavity. This allows for a mirror to achieve both positive and negative focusing (Moghimi, 2015).

Funding support:

NSF, MBRCT, CIHR

Students:

Sarah Lukes, Mohammad Moghimi, Tianbo Liu, Krishna Chattergoon

Collaborators:

Revibro Optics, LLC

Concept

Light reflecting from a curved mirror is focused, much the same way as if it passes through a glass lens. A reflective membrane that may be deformed to control its curvature can therefore act as a variable focus lens. Free-standing membranes fabricated using MEMS technology may be deformed under electronic control for fast and precise adjustment of an instrument focus. More complicated membranes may provide simultaneous correction of optical aberrations while adjusting focus, leading to very high quality imaging throughout a range of focus. With multiple focus adjustment elements in an instrument, we can implement more sophisticated operations such as variable magnification (optical zoom). Focus adjustment and zoom in conventional instruments is accomplished with physical translation of lenses, requiring motors, cams and other complex mechanisms that do not miniaturize easily. A variable focus membrane lens, on the other hand, could readily be used for focus or magnification control in endoscopic or even catheter-based instruments measuring only a few millimeters in diameter. Next generation membranes with improved range of motion may even provide focus and zoom capability for your smart phone camera.

Publications

Moghimi, M.J.; Dickensheets, D.L., "Electrostatic-Pneumatic Membrane Mirror With Positive or Negative Variable Optical Power," IEEE J. Microelectromechanical Systems, vol.24, no.3, pp.716-729, June 2015.

S. Lukes and D. Dickensheets, "Agile scanning using a MEMS focus control mirror in a commercial confocal microscope", Proc. SPIE 8949, pp. 89490W—89490W-11, 2014.

Moghimi, Mohammad J., Krishna N. Chattergoon, Chris R. Wilson and David L. Dickensheets, "High speed focus control MEMS mirror with controlled air damping for vital microscopy," IEEE J. Microelectromechanical Systems, Vol. 22, No. 4, pp938-948, 2013.

Sarah J. Lukes, David L. Dickensheets, "SU-8 2002 Surface Micromachined Deformable Membrane Mirrors," IEEE J. Microelectromechanical Systems, Vol. 22, No. 1, pp94-106, 2013.

Brant M. Kaylor, Christopher R. Wilson, Nathan J. Greenfield, Peter A. Roos, Eric M. Seger, Mohammad J. Moghimi and David L. Dickensheets, "Miniature non-mechanical zoom camera using deformable MOEMS mirrors," Proc. SPIE 8252, 82520N (2012).

Mohammad J. Moghimi, B. Jeffrey Lutzenberger, Brant Kaylor, David L. Dickensheets, "MOEMS deformable mirrors for focus control in vital microscopy," Journal of Micro/Nanolithography, MEMS and MOEMS, 10(02), 023005, 1 April 2011.

Mohammad J. Moghimi, B. Jeffery Lutzenberger, Kyle Oliver, Steven Gates, Xue Xiaohu, Brant Kaylor, David L. Dickensheets, "An improved focus control mirror using SU-8 wafer bonding process," SPIE Vol. 7930, January 24-27, 2011.

Sarah J. Lukes, David Lämmle, David L. Dickensheets, "Surface micro-machined SU8-2002 membrane mirrors for focus control," SPIE Vol. 7594, January 23-28, 2010.

Sarah J. Lukes, Phillip A. Himmer, Eric J. Moog, Steven R. Shaw, David L. Dickensheets, "Feedback Stabilized Deformable Membrane Mirrors for Focus Control," Journal of Micro/Nanolithography, MEMS and MOEMS, Vol. 8, 043040 (2009).

Erwin Dunbar, Matthew Leone, Sarah Lukes, David L. Dickensheets, “Polymer deformable membrane mirrors for focus control using SU-8 2002,” 2008 IEEE/LEOS International Conference on Optical MEMS, Freiburg, Germany, August 11-14, 2008.

David L. Dickensheets, “Requirements of MEMS membrane mirrors for focus adjustment and aberration correction in endoscopic confocal and optical coherence tomography imaging instruments,” J. Micro/Nanolithography, MEMS and MOEMS Vol. 7, 021008, Apr. 30, 2008.

Phillip A. Himmer, David L. Dickensheets and Robert A. Friholm, “Micromachined silicon nitride deformable mirrors for focus control,” Optics Letters, Vol. 26, No. 16, pp 1280-1282, August 2001.