Instrumentation

Featured Instruments

Micro-CT

Housed in a -10C cold chamber, the Bruker Skyscan 1173 is the ideal instrument for characterizing the microstructure of snow samples and/or other porous materials.

The micro-computed tomography system Bruker Skyscan 1173 (micro-CT), is used for obtaining high precision geometry data of small to mid-sized samples in a nondestructive way. Inside a scanning chamber, hundreds of x-ray projections are taken from the sample. From these, a reconstruction algorithm is able to produce a 3D-volume representation of the sample. This so called 'voxel image' contains all features from the inside of the sample that were originally not visible from the outside. Depending on the sample size, resolutions down to 5 microns are possible.

| Spec. | Value |

|---|---|

| X-ray source | 40-130kV,8W ,<5 µm spot size |

| X-ray detector | distortion-free Flat Panel sensor 2240x2240 pixels,12-bit |

| Maximum object size | 140mm in diameter, 200mm in length (100-140mm scanning length) |

| Spatial Resolution | <4-5 µm detail detectability, 7-8 µm low-contrast resolution |

| Reconstruction | GPU-accelerated FDK reconstruction |

| Radiation safety | <1 µSv/h at 10cm from the instrument surface |

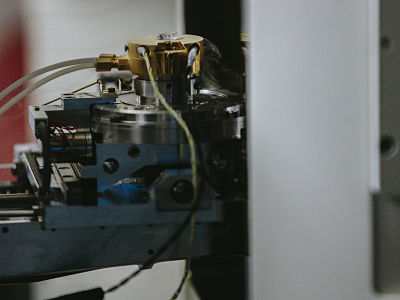

Materials Testing Stage

The Material Testing Stage (MTS) allows combining micro-CT imaging with tensile and compression testing. During scanning the sample is subjected to a controlled load, while having the loading curve displayed on-screen in real time.

This material testing stage applies an accurate force measured by load cell with deformation measurements by precision displacement sensor. The stage can be used in 2 modes: a continuous mode for compression or tension up to the maximum allowable load or until the maximum displacement; and a predefined mode in which the user can specify either the load or the displacement that should be reached. The loading curve is displayed on-screen in real time; load/displacement or stress/strain curves can be displayed and saved. The object can be held under a specific single or multiple loading(s) for micro-CT scanning.

Specifications:

- Maximum force: 440N

- Displacement sensor accuracy: ± 0.01mm

- Load measurement accuracy: ± 1% of the full range

- Maximum object diameter: 20mm

- Maximum travel: 5.5mm

- Max object height for compression: 23mm

- Max object length for tensile tests: 18mm

Wind Tunnel

This benchtop windtunnel is housed in the Structural Testing Chamber of the SRL, capable of temperature down to -40C and wind speeds up to 20 m/s.

Originally used on behalf of ice physicist, Dr. Victor Petrenko at the Thayer School of Engineering at Dartmouth College, this wind tunnel has been modified at MSU to accomodate studies primarily on blowing snow.

Specifications:

- Linear test volume: 1 m (length) x 30 cm x 30cm (cross-sectional area)

- Min Wind Speed: 1m/s

- Max Wind Speed: 20 m/s

MTS C43 Load Frame with Environmental Chamber

Mechanical Testing Systems (MTS) Uniaxial Load Frame, 30 kN Load Cell, Environemental Chamber

Uniaxial load frame with environmental chamber for testing small snow and ice specimens. Programmable loading as well as constant load or constant displacement rate tests with TWElite software. The load frame and environmental chamber can apply 30kN loads at temperatures ranging between –130C to 315C. Max Speed: 1020 mm/min, ,

Specifications:

- Force Capacity: 30kN

- Max Speed: 1020 mm/min

- Vertical Test Space: 1500 mm

- Temp Range: -129C to 315C

- Internal Dimensions: 254x254x610 mm

Nikon Eclipse 80i Microscope

An epi-fuorescence microscope with a cold stage

The Nikon Eclipse 80i microscope is setup for digital imaging, with aQImaging Retiga 2000R CCD camera that is designed for high precisionquantitative analysis in low light / brightfield / darkfield / fluorescenceimaging. The microscope system includes a THMS600 heating and freezingmicroscope stage that can provide temperatures ranging from -195°C to600°C. An additional heating/cooling stage (BCS 196) provides

temperatures ranging from -195°C to 125°C, with precise heating andcooling rates of 0.01°C to 150°C/min.

Anechoic Radar Chamber

Constructed with radar absorbing foam (1-18 GHz).

The anechoic radar chamber was constructed as a modular unit that can be moved in and out of the various cold rooms of the SRL. It is currently used for laboratory-based snow radar experiments and consists of wood panelling lined by certified radar absorbing foam (1-18 GHz). Inner Chamber Dimensions: 80cm x 80cm x 190cm

Gatan C1001 Cryo-stage for SEM

Used for imaging and analysis of ice, snow, and bio-materials.

Digitally-controlled cryo-stage for dedicated use with the Zeiss Supra 55VP FEM-SEM. Cooled with LN2 gas, capable of maintaing temperatures as low as -190C.

SEM is located in the Image and Chemical Analysis Laboratory (ICAL) at MSU.

Cryo-stage for Confocal Raman Spectroscopy

Used for chemical analysis of ice and snow samples.

Linkham cold-stage dedicated to a Horiba LabRAM HR Evolution NIR Confocal Raman Microscope. Cooled with LN2 gas, capable of maintaining temperatures as low as -180C. Optimized for the visible to IR range (400nm-2500nm).

Raman Microscope is located in the Chemical Imaging Lab of the Center for Biofilm Engineering at MSU.

Full Inventory

|

Room

|

Instrument Name

|

|---|---|

|

CC-1

|

Delta band saw (for cutting ice cores)

|

|

Nikon microscope

|

|

|

CC-2

|

SKYCAN 1173 MicroCT

|

|

Nikon OPTIPHOT-POL Microscope

|

|

|

WILD HEERBRUGG Microscope w/Camera Mount

|

|

|

Canon EO4 40D (Mounted to WILD Microscope)

|