MSU Pesticide News - April 27th, 2015

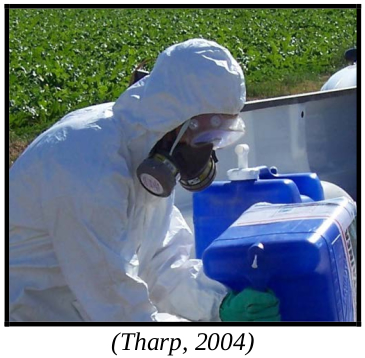

Respiratory Protection of Increasing Concern: A Focus on Paraquat

The use of highly toxic pesticides that require respiratory protection were on the decline for over two decades. Recently, the use of one highly toxic active ingredient is on the rise due to glyphosate resistant kochia in Montana. This active ingredient is known as paraquat. Paraquat is in such formulations as Devour®, Firestorm®, Helmquat 3SL®, Gramoxone SL®, Cyclone SL 2.0®, Bonedry®, Willowood Paraquat 3SL®, Paraquat Concentrate® and Parazone 3SL Herbicide®. Paraquat is a photosynthesis inhibitor and acts as a non-selective contact herbicide.

Applicators should use this pesticide product with care as it is classified as a category 1 substance with the signal word ‘Danger – Poison’. This signal word implies that this pesticide product is highly toxic through multiple routes of entry. When using paraquat products applicators should remember to:

- Have buffers between the pesticide application and sensitive areas (livestock, people, pets).

- Follow all re-entry requirements on the pesticide products label.

- Wear proper personal protective equipment.

Personal Protective Equipment

Personal protective equipment (PPE) requirements are usually on the first or second page of the product label under Precautionary Statements. Table 1 represents the PPE requirements for applicators while using the paraquat formulation known as Paraquat Concentrate®. PPE requirements for applicators not mixing and loading include protective eyewear, long sleeve shirt and pants, protective eyewear, chemically resistant gloves and the use of a NIOSH approved particulate filtering respirator with any N, R or P filter with an approval prefix of TC-84A. Mixers and loaders must also wear a chemical resistant apron and face shield.

Personal protective equipment requirements for Paraquat Concentrate

Applicators and other handlers (other than mixers and loaders) must wear:

Long-sleeved shirt and long pants; Chemical resistant gloves - Category A (e.g., barrier

laminate, butyl rub

ber, nitrile rubber, neoprene rubber, natural rubber, polyethylene, polyvinyl chloride

(PVC) or viton); Shoes

plus socks; Protective eyewear; NIOSH-approved particulate filtering respirator equipped

with N, R or P class

filter media. The respirator should have a NIOSH approval number prefix TC-84A. It

is recommended that

you require that respirator wearer to be fit tested, and trained in the use, maintenance

and limitations of the

respirator.

Mixers and loaders must wear:

- Long-sleeved shirt and long pants

- Chemical resistant gloves - Category A (e.g., barrier laminate, butyl rubber, nitrile

rubber, neoprene rubber,

natural rubber, polyethylene, polyvinyl chloride (PVC) or viton) - Shoes plus socks

- Chemical resistant apron

- Face shield

- NIOSH-approved particulate filtering respirator equipped with N, R or P class filter

media. The respirator

should have a NIOSH approval number prefix TC-84A. It is recommended that you require that respirator

wearer to be fit tested, and trained in the use, maintenance and limitations of the respirator.

Respirator Requirements

Respirator requirements can be quite confusing due to the wide variety of respirators on the market. Some product labels contain designations such as TC-84A, TC-21A, TC-23C, TC-14G, TC-13F and TC-19C (Table 2). The product label for Paraquat Concentrate® calls for a TC-84A respirator. TC-84A respirators include:

#1 Filtering face-piece respirator (N, R, or P)

#2 Air Purifying Respirator (APR) with particulate filters (N, R or P)

#3 Air Purifying Respirator (APR) with combo chemical cartridge and filter (N, R or P filter)

The Paraquat Concentrate® product label further requires fit testing. Applicators using this product must wear any TC-84A option after proper fit testing. Applicators using any category 1 (Danger – Poison) liquid formulation are urged to wear only respirators that can be fit tested even if the product label doesn’t describe fit testing. There are many other types of respirators required on other pesticide product labels including self-contained breathing apparatuses, powered air respirators and others (Table 2).

|

Designation

|

Filter Type

|

|---|---|

|

TC-84A

|

Filtering face-piece respirator (N, R or P)

Air purifying respirator with particulate filers (N, R or P) Air purifying respirator with combination chem cartridge and filter (N, R or P) |

|

TC – 21C

|

Air purifying respirator with chemical cartridges

Powered air purifying respirator with chemical cartridges Powered air purifying respirator with combination chemical cartridge & filter (HE) |

|

TC – 23C

|

Air purifying respirator with chemical cartridges

Powered air purifying respirator with chemical cartridges Powered air purifying respirator with combination chemical cartridge & filter (HE) |

|

TC – 14G

|

Gas mask with or without particulate filter (N, R or P)

Tight-fitting powered air purifying respirator w/ gas canister with/without HE filter |

|

TC – 13F

|

Self-contained breathing apparatus

Supplied-air respirator with a self-contained escape bottle |

|

TC – 19C

|

Supplied-air respirator

|

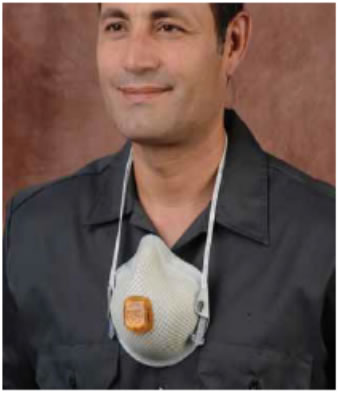

Fit Testing

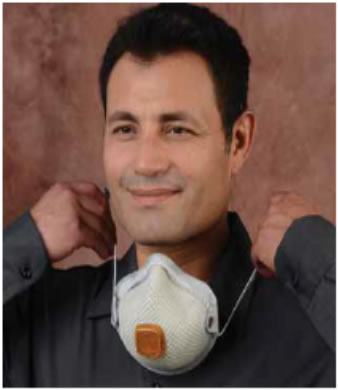

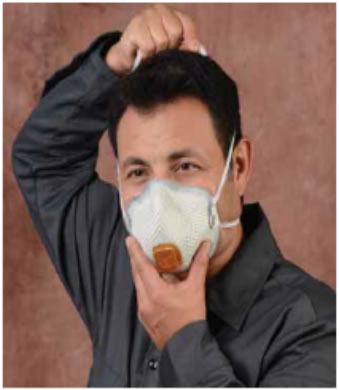

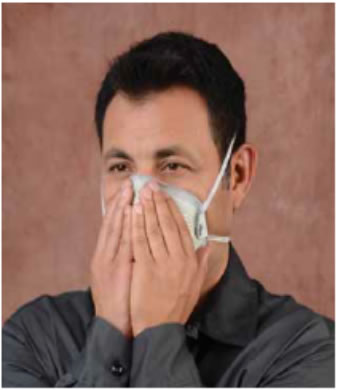

Fit Testing. Fit testing is a method for selecting only respirators that fit properly. Pesticide applicators should perform a negative pressure test by covering the surface or hose where air is inhaled and breathe in. If the mask is properly sealed, it should collapse on face with no signs of leakage. Re-adjust mask until you get a seal or purchase a mask of a more appropriate size. Be aware that facial hair will obstruct the proper seal of a respirator. Even a face piece respirator has fit testing instructions that should accompany the respirator when purchased (Figure 1).

Figure 1. Fit testing of a NIOSH approved facepiece respirator according to MOLDEX fitting instructions (MOLDEX Fitting Requirements; 9900-037 REV A10/12).

| Photo | Instructions |

|---|---|

|

Step 1

|

|

Step 2

|

|

Step 3

|

|

Step 4 To hang around neck:

Or:

|

Types of Filters and Cartridges

The ‘Paraquat Concentrate® product label also calls for the use of particulate filters rated as N (NOT resistant to oil), R (RESISTANT to oil) or P (oil PROOF). Filter efficiency is rated as 95, 99 or 100. For example you could have a label that specifies N, R or P filters with an efficiency rating of 100. This is referring to N100, R100 or P100 filters for your respirator. The product label for ‘Paraquat Concentrate®’ allows for the use of any N, R or P filter.

Chemical cartridges remove gases and vapors but they don’t remove particulates. The most common cartridge or canister required on the product label remove organic vapors (OV). Chemical cartridges should be changed if you detect chemical odors while wearing respirator. The Paraquat Concentrate product label does not require the use of a chemical cartridge.

WPS respiratory requirements described in this article are not all inclusive. Applicators should be aware of the full WPS respiratory requirements as defined in 29 CFR 1910.134

Further Information

For more information on respirators see the CDC NIOSH requirements or see pages 96–100 of the National Pesticide Applicator Core Manual [expired link]. For other questions contact Cecil Tharp (MSU Pesticide Education Coordinator; 406-994-5067; [email protected]).