3D Printers

The Makerspace has a variety of 3D printers which are available for use by students, faculty, and staff! 3D printing is a great method for rapid prototyping, developing unique and functional objects, or making replacement parts. Makerspace employees can help guide you through the process no matter your background.

FDM vs. SLA

FDM (Fused Deposition Modeling) printers use thermoplastic filaments that are melted onto a build plate in discrete layers, while SLA (Stereolithography) printers use a UV light to cure liquid resin into the desired shape. FDM tends to be a quicker process, however SLA can achieve a much higher resolution.

FDM Printer

Prusa MK3 Printers

SLA Printer

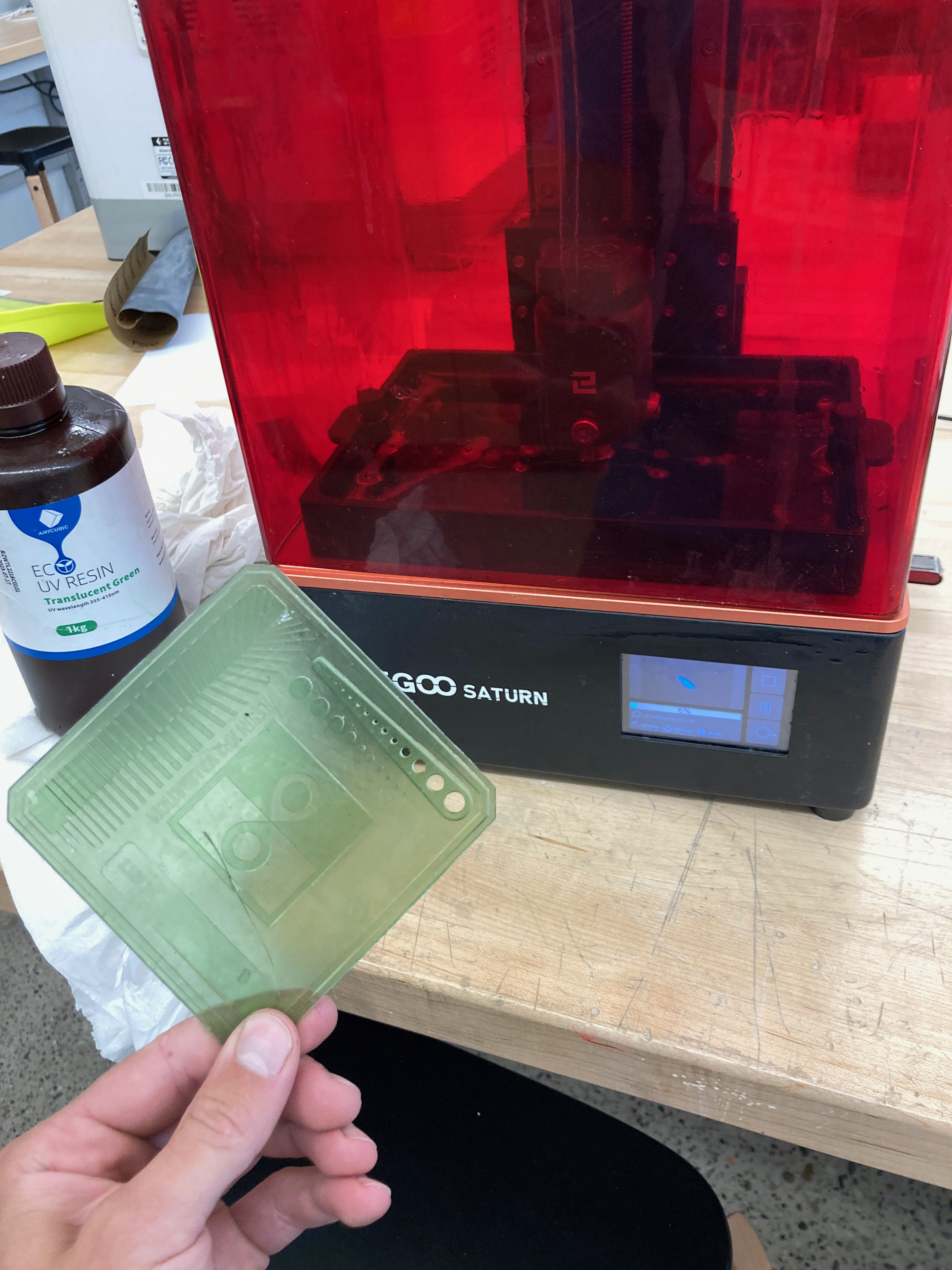

Elegoo Saturn printer with a test print

How do I print at the Makerspace?

- Create or find the file you want to print

- Save it as an .stl, .step/.stp, .3mf, .obj

- Give the file to a Makerspace employee for slicing

- The Makerspace employee will confirm your choices for infill, material, supports

- Leave your name, email, and GID (or index number for research prints) with the Makerspace employee

- Pick up your print once it is done!

- You will be billed on your CatCard after you pick up your print

All prints must be sliced by a Makerspace employee!

How much does 3D printing cost?

Please see the pricing page for the most up to date list of materials and prices.

How long does 3D printing take?

It can vary wildly based on the printer, material, infill, and supports. As a rule, SLA printing is slower than FDM printing, but SLA printing results in much more detailed prints. Makerspace employees can help you find the option that best suits your needs.

What materials can be 3D printed?

|

FDM Printers

|

SLA Printers |

|---|---|

|

PLA

|

Clear Resin

|

|

PETG

|

Opaque Resin

|

|

ABS

|

Tough Resin

|

|

TPU

|

High Temperature

|

|

Nylon

|

Castable

|

|

Polycarbonate

|

|

|

Note: Materials are subject to availability, contact the Makerspace if you have specific

needs

|

|

FDM Materials:

For basic prototypes and non-structural projects, PLA will meet the needs of most users, it is a forgiving material that performs decently well under low loads and thermal conditions. PETG is a step above PLA, and is has higher resistance to chemicals and fatigue. ABS can handle higher loads than both PETG and PLA but requires an enclosure to minimize warping during the printing process.

SLA Materials:

Clear and opaque resins both result in high detail prints that are suitable for prototypes, minis, and other parts that do not require high strength properties. Clear prints can show internal details but the level of transparency may change over time. Tough resin is similar to ABS, able to handle higher loads and serve as a functional part. High temperature resin has the benefit of holding its shape above 200 degrees Celsius. Castable resins can be used in investment casting processes.