Lean Enterprise

Let us help you create and maintain an organization with improved cash flow and profitability, increased throughput and reduced chaos, while improving team morale. Harness the power of your team members with the following Lean services.

Lean Manufacturing: Begin the Journey

Looking for a way to reduce your costs and increase your throughput? Want to stay ahead of the competition?

- Does improved quality, cost, and delivery interest you?

- Want to win the next right customer with best-in-class on-time delivery?

- Do you want to develop and retain a high-performance workforce?

If YES, you should get started on a Lean transformation, to develop an enterprise culture of waste reduction and continuous improvement.

What are the benefits of a Lean Manufacturing System?

- Reduced costs

- Increased throughput

- Streamlined processes

- Improved communications

- Reduced process variability

- Schedule integrity

- Improved on-time delivery

How can MMEC help implement a Lean transformation?

MMEC works with you and your team to understand your business and its processes. Together, we map out your company processes, investigating new methods and identifying opportunities for reducing non-value added activity. Once this is complete, our team of expert field engineers work with you and your team to create and implement a long-term plan for continuous improvement in your organization.

Lean Enterprise Certification Program

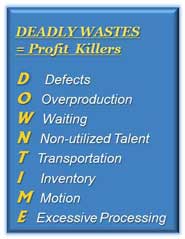

The LEAN Enterprise Certification Program (LECP) is a 10-session training program led by MMEC's Business Advisors to help build internal capacity by providing your key staff with a deeper working knowledge of the principles and practices of LEAN from key thought leaders and noted authors. Developing internal leadership for your LEAN initiatives will help weed out the Deadly Wastes that equate to D-O-W-N-T-I-M-E, the Profit Killers in your business with more focus and consistency. The final session is the 3-hour SME exam, proctored by MMEC.

Lean Enterprise: Inventory Management

Contents of this section under construction

Lean Enterprise: Office & Administration

Don't let office work slow your company down!

Office functions eat up more than 70% of the time before a product goes out the door! In today’s intensely competitive marketplace, aligning efficiencies and responsiveness across the enterprise is imperative. Lean for office and administration applies successful Lean principles to office functions such as order entry, quoting, scheduling, and design & engineering. Many organizations – even non-manufacturers – are discovering that Lean applied to the office can offer even greater improvements to the bottom line and free up resources for growth.

What are the benefits of Lean for Office & Administration?

- Increase operational effectiveness

- Provide better clarity to job roles & functions

- Shorten lead time between order in & order out

- Significantly reduce paper waste & space needs

- Improve productivity and profitability

- Enhance customer relationships

How Can MMEC Help You Achieve Lean Office/Administration?

Beginning with a day of training and live simulation using today’s technology tools, you & your staff will learn the best way to see a process, identify wastes and how to apply the appropriate Lean tools to create a more effective organization. MMEC works with your business to help you understand the value stream in your administrative operations. Using this interactive approach, we focus on the unique application of Lean to an office environment where processes are not always visible.Maximize the training value with a select Kaizen event day in your plant to get you started…

Lean Enterprise: Plant Layout

Does my company need Plant Layout Assistance?

- Unorganized material flow?

- People bumping into each other or products?

- Having trouble finding your parts?

- Employees spending more time moving items than actually working on them?

- Moving into a new building?

- Expecting to add more equipment or workstations?

If YES, your company could benefit from Plant Layout Assistance….

Plant Layout Assistance is…

Designing plant layout to meet manufacturing requirements in the most efficient manner. Well planned and designed layouts provide more balanced production lines that help identify bottlenecks, allow inventory to be tracked from start to finish, and reduce material handling and wasted time spent looking for an item.

What are the benefits of Plant Layout Assistance?

- More efficient production

- Delivery when promised

- A safer work environment

- Improved space utilization

- Reduced risk of materials damage

How can MMEC help with Plant Layout?

MMEC works with you and your team of managers and production employees to examine the production requirements and assists you in designing a plant layout that best fits the production needs. Initially, we gather information about your product and production processes. We learn how you make, move, store, package, and ship your products. Then we examine the production process in relation to the facility layout and help you develop a facility layout to best fit your product flow and manufacturing needs.

Lean Product Development

Looking for ways to align your product development process with your evolving Lean culture?

This section under construction.

Lean Enterprise: Setup Reduction

Looking for ways to reduce production costs and increase throughput?

- Does switching production from one product to another require a long setup to prepare equipment or workstations?

- Do your customers want or need quicker delivery?

- Do your processes currently, require large production batches?

- Do you operate in a high mix/low volume environment?

- Do you want to reduce production costs?

If YES, you may benefit from Setup Reduction Assistance….

What is Setup Reduction?

Setup reduction is a process improvement activity targeted at reducing the amount of time and effort required to change over production from one product to another. Ideally, the goal should be to reduce the setup activity to less than 10 minutes. Setup reduction facilitates smaller batch sizes without increased costs.

What are the benefits of setup reduction?

- Faster response to customer needs from shortened lead times

- Lower production costs

- Smaller batch sizes which reduce floor inventory and space requirements and give quicker recognition of product defects

- Increased productivity

- Improved workplace organization

- Improved quality and reduced scrap

How can MMEC help your company initiate a setup reduction improvement activity?

MMEC works with you and your team to understand your business and your production process. We help you identify the opportunities for setup reduction and how these will benefit your operations. The experts at MMEC can help plan and guide your setup reduction activity to completion.

We won't just tell you how to do it, we'll work with you to get it done.

Lean Enterprise: Value Stream Mapping

Confused about how to implement "lean" manufacturing in your company?

- Are you unsure where in your production process you should start making lean changes?

- Are you wondering what "lean" improvements will provide the most benefits and how to organize lean activities?

- Would a simple, visual representation of your process help communicate the need for improvement and where to start?

If YES, your company will benefit from Value Stream Mapping...

What is Value Stream Mapping?

Value Stream Mapping is a pencil and paper tool that helps you to see and understand the flow of material and information as a product makes its way through your production process. Value stream mapping is a way to evaluate the current production process, identify the value-added steps, and envision the improved (future) production process.

What are the benefits of Value Stream Mapping?

- Helps visualize the production process at the plant level.

- Identifies waste in each step of the production process.

- Ties together lean concepts and techniques to enable improvements that show up in your organization's bottom line.

- Provides a clear plan for implementing improvements to the production process to reduce costs.

- Leads to a future-state map for continuing the journey.

How can MMEC help me improve my production process with Value Stream Mapping?

MMEC works with you and your team to understand your business, your products, and your process. Together, we will "map" the product information, and material value flows in your plant. The resulting value stream map will be used to identify and link improvements that increase overall performance. Once the improvements are identified, MMEC can help you develop an implementation plan to guide the improvements to completion and get you started with future-state improvements.We won't just tell you how to do it, we'll work with you to get it done.

See also Lean Enterprise: Plant Layout