Mash Master

Brewing has historical roots reaching back to early civilization. Over that long history both the ingredients and brewing styles have adjusted with the day. Mashing, the important brewing step converting grain starch into sugar for fermentation, has itself developed into multiple variations. From decoction, and temperature programmed to single infusion, here we discuss the purpose of mashing in the brewhouse and brew styles which fit the different methods.

The initial stages of brewing involve milling malted and (potentially) adjunct grains, then mixing them with heated water to allow grain starch and protein reserves to solubilize into a liquid wort. This solubilization, or conversion, is a key aspect providing sugars and amino acids for yeast fermentation and health. Different grains have different needs, produce different beer qualities, and their selection combined with the mashing method can target particular beer styles. Each brewer must work within their equipment capabilities, but mashes in a way to create a blend of fermentable (small sugars) and unfermentable (larger sugars and partially digested starches) to fit profile. The ratio of fermentable and unfermentable sugars will play into the alcohol level and body of the beer.

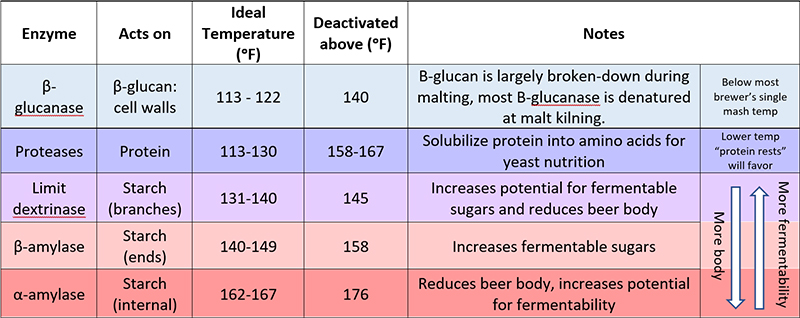

Enzymes are the workhorse allowing solubilization to occur. There are several critical enzymes and each works best at certain temperatures. Brewers target temperatures to maximize mash efficiency depending on desired style. Five key enzymes allowing conversion are shown in the table below. Mashing centralizes around temperature to favor these enzymes. The most common mash regime found in Craft Breweries today is a single infusion mash – which typically falls around 149ᵒF, but can push higher to favor beers with more body or lower to favor highly fermentable light bodied beers. The single infusion mash is straight forward as it requires heating water to the desired temperature and directly mixing it with the brewing grist, then holding that one temperature for a period of time, typically 1 – 1.5 hours. A single temperature won’t be ideal for all enzymes but selecting a temperature like 149ᵒF allows for enough action from key enzymes for conversion.

Lager mashing targets several temperatures in a step regime. Starting low and going through a series of temperature rises this allows malt enzymes with varying heat tolerances to act successively, producing a wort with maximized starch and protein extraction and resulting in very light body beers. This step type mash is useful for under modified malts (traditionally lager malts are intentionally malted to lower modification) as it offers several rests for full conversion of malt components. Rests can include a 45-minute hold at 104-133ᵒF (favors protein conversion), followed by heating to 144-149ᵒF for a 45-minute hold (favors starch conversion), before a final heat rise to 167ᵒF to ease filtration. Often, modern-day malts are very well modified reducing the need for this intensive process. Some beers however are stylistically favored by programmed mashes, for example some Bavarian brewers will use rests to favor the development of organic compounds that yeast will later transform into aromatics typical of the Bavarian style.

Cereal cooking is a mashing practice which allows the use of un-malted grains such as corn and rice. Although starch is the primary energy reserve across brewing grains, starches are not all the same. Different grains will have different starch gelatinization temperatures. As a good example of starch gelatinizing, think of your oatmeal – after preparation it has a thick creamy texture that is allowed because the oat starches have gelatinized with cooking. Products like rolled oats or instant oats are actually pre-gelatinized as part of their processing. Gelatinization can be thought of like popcorn popping, when heated to the proper temperature starches change structure similar to popcorn bursting open. This action is important for all brewing starches as it makes them more accessible to enzymes for conversion. Grains like rice and corn have particularly high gelatinization temperatures – meaning that they must be cooked to boiling before being included in the mash with malted barley, which has a much lower gelatinization temperature. The boiling must take place in a separate vessel to prevent destruction of the barley enzymes which are temperature sensitive. Not all breweries have a cereal cooker, a specific vessel for this process, but are able to incorporate these high temp grains by using products which are pre-gelatinized like flaked corn and rice. Pre-extracted sugar products like corn syrup are another option. Using corn and rice in a brew will create very light clean beers, examples include American and Pre-Prohibition Lagers.

Decoction mashing is a traditional and rigorous process once standard for most breweries, but largely unused in modern-day practice as it is energy intensive and less necessary with highly modified malts. The basic principle is that a portion of the mash is separated, boiled, then returned to the main mash. The boiling process breaks down cell wall components of under modified grains and (of particular importance before thermometers were available) the tempering achieved when mixing boiled portions back to the main mash allows achievable and repeatable step rests like those of lager mashing. German brewers maintain that the decoction method develops malt character, depth, and superior foam. German and/or Renaissance breweries celebrating traditional styles would be a good place to find decoction brews.

More so than any where in the world American Craft Brewers have taken to the wide variation of methodologies and ingredients to play into their wildly adventurous palates. As you explore across MT be sure to strike up conversations with your tenders to learn about what process’s our locale brewers may be employing to make traditional styles and/or bespoke flavors!