Resource Center

Welcome to the Montana State University

Barley Resource Center!

What is malt?

Malt, in terms of beer or distilling, is an important natural ingredient most often derived from barley which largely dictates many aspects of the beer in your glass - including: alcohol content, flavor, mouth feel, and color.

Learn the process - Greenhouse to Glass, in this presentation from Montana Craft Beer Week

Why do we say "Know Barley, Know Beer"?

(when there are also other grains malted?)

Barley has two important aspects as a malt that other grains don't live up to. Barley has a husk and produces more enzymes than other grains. These are important attributes to the brewing process:

1) the barley hulls aid in beer filtration - beers made without enough barley need added rice hulls or other filtration aids

2) The high enzyme potential of barley (which has a multi cell aleurone layer to produce more enzyme compared to the single cell layer of other grains) allows efficient conversion of starches to sugars for fermentation. Beers utilizing adjuncts such as rye, oats, rice, corn, wheat etc benefit from a high % of barley base malt in the grist bill to provide enzymes for full starch conversion.

How is malt made?

Starting with grain from the field, malting follows three basic stages: Steeping, germination, kilning

Steeping:

The steeping phase brings grain up to ~45% moisture (from ~12% at harvest) over a period of roughly 2 days. Alternating between periods of water submersion (steeps) and air rests, the grain takes up moisture which triggers a sense of "spring rain conditions". This moves the grain into a germination phase.

Germination:

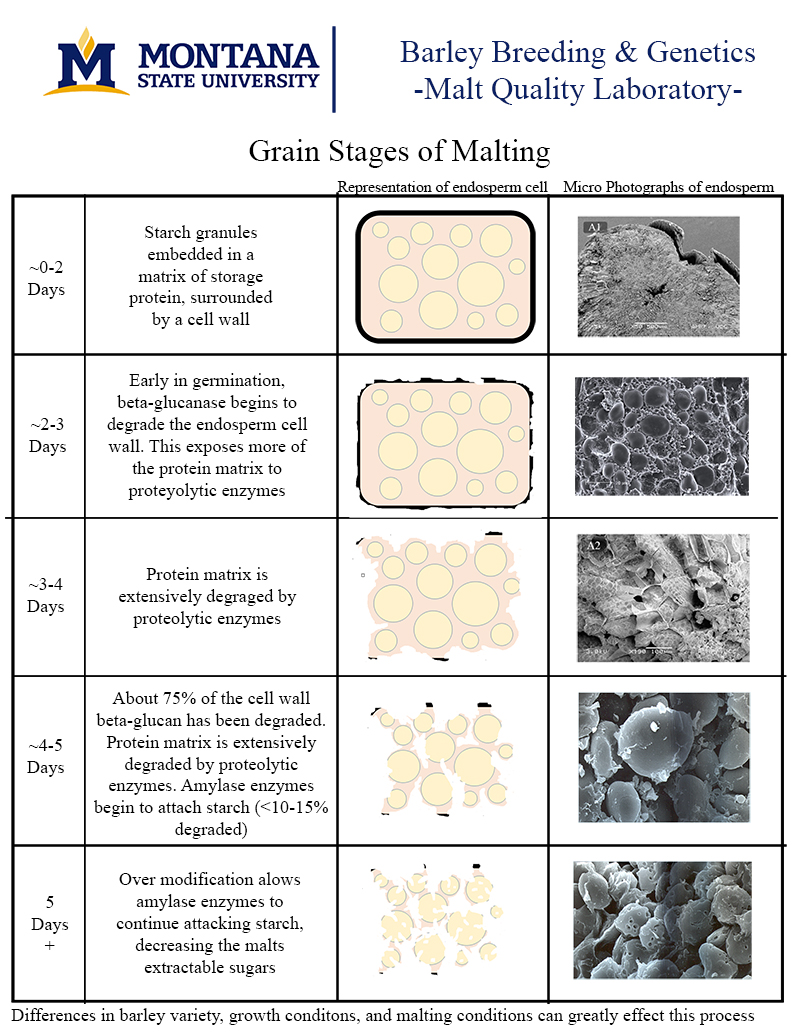

This phase is typically 3-5 days and allows the biological changes in the grain which break down cell walls and protein in the grain, exposing starch granules and preparing them for the brewing process.

Kilning:

For base malts this phase takes roughly a day and utilizes low slow heat to dry the grain down to ~4-5% moisture, making it stable for storage. Specialty malts can also be made in the kiln when modifying timing, moisture, and temperature. Much of the color and flavor in malt is developed during the kilning phase.

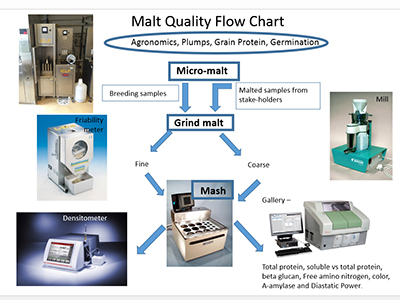

Grain Stages as Malting Progresses

Three Fantastic Videos on the Malt Process

We couldn't decide which we liked best, so here are all three - with points to why each is great!

We hope you find the content of these pages useful, informative, and interesting. We continually work to upload new material an updates, and we welcome your feedback any time - just an e-mail away!

Montana State University is committed to offering accesable content to all - if you are struggling to read or access anyting on our website please reach out to [email protected] so that we can assist!

Cheers!