Mineralization Technologies

Wells are constructed by drilling a hole, inserting a steel casing, then cementing in the annular space between the outside of the casing and the rock wall of the hole. When the well is used, pressurizing and depressurizing the casing can eventually case small cracks in the cement and lead to undesirable fluid migration up the annulus. Because these pathways are very small, they are difficult to re-seal. The current technology used is fine cement, but even fine cement can be too viscous to pump into these tiny cracks.

MSU researchers in the Energy Research Institute in collaboration with the Center for Biofilm Engineering have devised a strategy to plug small flow pathways in wellbores and in subsurface cement and rock. The strategy involves using an enzyme as a catalyst to form calcite minerals in the flow pathway. The enzyme can be delivered using s. pasteurii bacteria which contain the urease enzyme. These are biofilm forming bacteria and can “glue” themselves in place along the flow pathway. If a calcium source is provided, the enzyme in the bacteria catalyzes mineral formation “growing” new rock in the flow pathway.

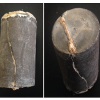

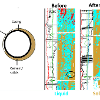

This approach was tested in the lab on various types of rock core and at different scales (1 inch diameter up to 30 inch diameter) and was found to dramatically reduce permeability and to have mechanical strength similar to cement.

MSU researchers and partners have also tested this technology in a well with an annular leak and successfully sealed the well.

MSU investigators in this work are Adie Phillips, Al Cunningham, Lee Spangler, and Robin Gerlach.

Publications

Phillips, A. J.; Lauchnor, E.; Eldring, J.; Esposito, R.; Mitchell, A. C.; Gerlach, R.; Cunningham, A. B.; Spangler, L. H., Potential CO2 Leakage Reduction through Biofilm-Induced Calcium Carbonate Precipitation. Environmental Science & Technology 2013,47 (1), 142-149.

Phillips, A. J.; Gerlach, R.; Lauchnor, E.; Mitchell, A. C.; Cunningham, A. B.; Spangler, L., Engineered applications of ureolytic biomineralization: a review. Biofouling 2013,29 (6), 715-733.

Phillips, A. J.; Eldring, J.; Hiebert, R.; Lauchnor, E.; Mitchell, A. C.; Cunningham, A.; Spangler, L.; Gerlach, R., Design of a meso-scale high pressure vessel for the laboratory examination of biogeochemical subsurface processes. Journal of Petroleum Science and Engineering 2015,126, 55-62.

Phillips, A. J.; Cunningham, A. B.; Gerlach, R.; Hiebert, R.; Hwang, C.; Lomans, B. P.; Westrich, J.; Mantilla, C.; Kirksey, J.; Esposito, R.; Spangler, L., Fracture Sealing with Microbially-Induced Calcium Carbonate Precipitation: A Field Study. Environmental Science & Technology 2016,50 (7), 4111-4117.

Mitchelli, A. C.; Phillips, A. J.; Kaszuba, J. P.; Hollis, W. K.; Cunningham, A. L. B.; Gerlach, R., Microbially enhanced carbonate mineralization and the geologic containment of CO2. Geochimica Et Cosmochimica Acta 2008,72 (12), A636-A636.

Mitchell, A. C.; Phillips, A. J.; Hiebert, R.; Gerlach, R.; Spangler, L. H.; Cunningham, A. B., Biofilm enhanced geologic sequestration of supercritical CO2. Int. J. Greenh. Gas Control 2009,3 (1), 90-99.

Mitchell, A. C.; Phillips, A. J.; Hamilton, M. A.; Gerlach, R.; Hollis, W. K.; Kaszuba, J. P.; Cunningham, A. B., Resilience of planktonic and biofilm cultures to supercritical CO2. Journal of Supercritical Fluids 2008,47 (2), 318-325.

Mitchell, A. C.; Phillips, A.; Schultz, L.; Parks, S.; Spangler, L.; Cunningham, A. B.; Gerlach, R., Microbial CaCO3 mineral formation and stability in an experimentally simulated high pressure saline aquifer with supercritical CO2. Int. J. Greenh. Gas Control 2013,15, 86-96.

Hommel, J.; Lauchnor, E.; Phillips, A.; Gerlach, R.; Cunningham, A. B.; Helmig, R.; Ebigbo, A.; Class, H., A revised model for microbially induced calcite precipitation: Improvements and new insights based on recent experiments. Water Resources Research 2015,51 (5), 3695-3715.

Ebigbo, A.; Phillips, A.; Gerlach, R.; Helmig, R.; Cunningham, A. B.; Class, H.; Spangler, L. H., Darcy-scale modeling of microbially induced carbonate mineral precipitation in sand columns. Water Resources Research 2012,48.

Cunningham, A. B.; Phillips, A. J.; Troyer, E.; Lauchnor, E.; Hiebert, R.; Gerlach, R.; Spangler, L., Wellbore leakage mitigation using engineered biomineralization. In 12th International Conference on Greenhouse Gas Control Technologies, Ghgt-12, Dixon, T.; Herzog, H.; Twinning, S., Eds. 2014; Vol. 63, pp 4612-4619.

Cunningham, A. B.; Lauchnor, E.; Eldring, J.; Esposito, R.; Mitchell, A. C.; Gerlach, R.; Phillips, A. J.; Ebigbo, A.; Spangler, L. H., Abandoned well CO2 leakage mitigation using biologically induced mineralization: current progress and future directions. Greenh. Gases 2013,3 (1), 40-49.

Cunningham, A. B.; Gerlach, R.; Spangler, L.; Mitchell, A. C.; Parks, S.; Phillips, A., Reducing the risk of well bore leakage of CO2 using engineered biomineralization barriers. In 10th International Conference on Greenhouse Gas Control Technologies, Gale, J.; Hendriks, C.; Turkenberg, W., Eds. 2011; Vol. 4, pp 5178-5185.

Codd, S. L.; Vogt, S. J.; Hornemann, J. A.; Phillips, A. J.; Maneval, J. E.; Romanenko, K. R.; Hansen, L.; Cunningham, A. B.; Seymour, J. D., NMR relaxation measurements of biofouling in model and geological porous media. Org. Geochem. 2011,42 (8), 965-971.