Malt Mineral Profile

"Beer is the most complex beverage known to man, and the role of water in brewing is equally intricate." -Palmer & Kaminski

Commonly, brewers don't consider malt in wort chemistry due to lack of available info.

Let's start considering malt contributions to our wort mineral profile!

Why Should We Care?

Beer Flavor:

- The ratio of chloride and sulfate can push a beer to taste more malty or more hoppy.

- Magnesium has been found to promote Maillard compound production affecting beer color and flavor.

- Potassium can taste salty at high concentrations.

- Sodium can round out beer flavor, accentuating the sweetness of malt, wheras high levels can creat a harsh sourness, and low levels can promote cleaner flavor.

- Iron can be detrimental to beer stability and quality and therefore should be as low as possible in beer. Higher levels can hamper starch conversion and promote hazy worts.

Brewing Process:

- Calcium improves enzyme activity and reduces formation of beer stone while increasing yeast flocculation and reducing diacetyl production. Monitoring calcium concentrations can be a key to consistent beer production.

- Silicates can be extracted from malt husks. High levels can cause slow runoff and haze in beer as well as promoting beer scale.

- Carbonates can result in less fermentable worts, unacceptable wort colors, difficult filtrations and less efficient separation of protein and tannins in hot and cold breaks.

- Phosphates are prevalent in malt and are important pH buffers, however high levels are found in brewery waste products, which can be problematic downstream.

For more detailed info on the individual minerals and their impacts follow this link!

Concept Overview

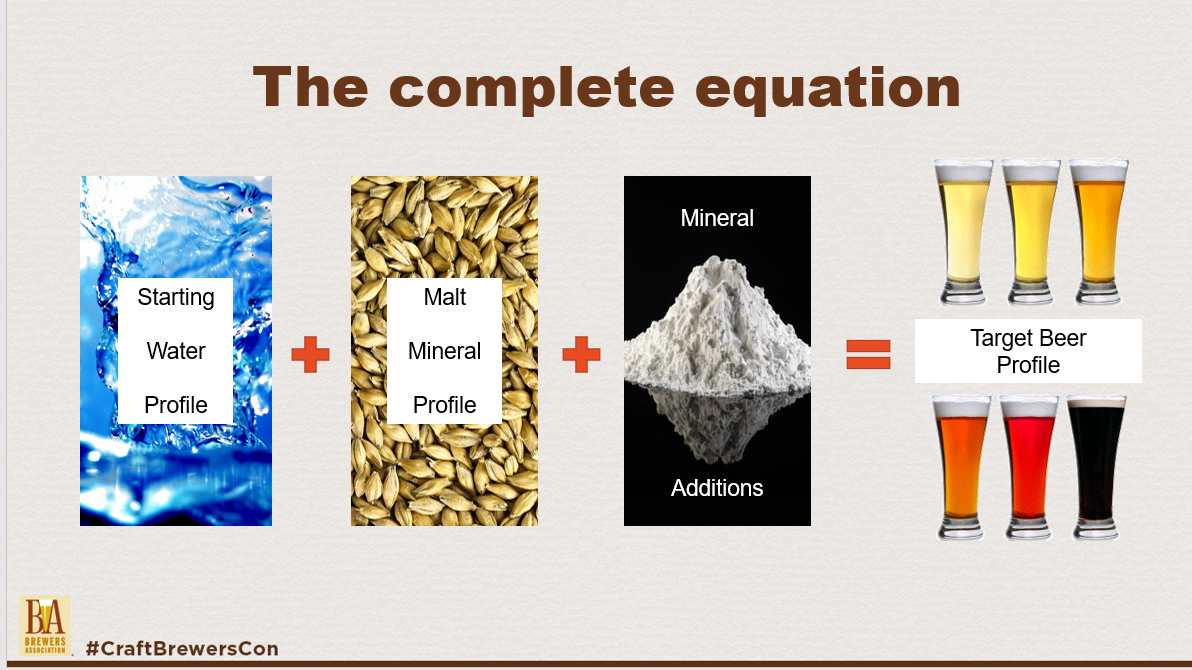

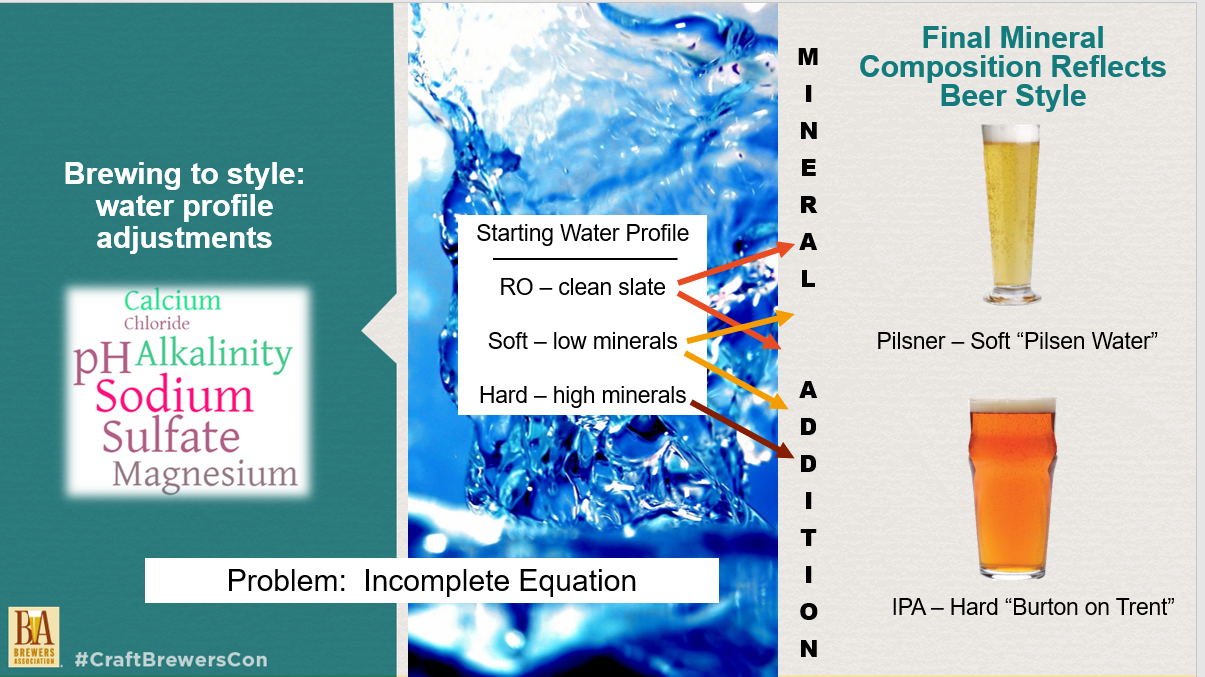

Consideration of brewingwater composition is commonplace in brewhouses. Typically, brewers will know the general composition of their water and adjust to suit the desired brewing profile. This process mostly does not consider malt contributions as the levels are not well characterized.

Common Brewing Process: Starting with a known water mineral profile (either a clean slate due to Reverse Osmosis (RO), or known profile from local or in house-water reporting, brewers adjust via addition of various minerals, targeting the water profile suited to historic beer profiles. Significant mineral contributions come from malt and are commonly not accounted for in brewing process.

Typical Mineral Levels -- Barley --> Beer

The table below lays out typical mineral profiles found along the barley to beer process - including barley, malt, and wort. The second table outlines common water profiles and values typically found in beer.

| Barley | Malted Barley | Wort: Ballast Point Brewing | Wort: MSU Preliminary | |

| Potassium | 4840 - 6280 | ... | ... | 317 - 508 |

| Sodium | 26 - 84 | 117 | 7 - 40 | 1 - 19 |

| Calcium | 440 - 770 | 1190 | 19 - 25 | 24 - 48 |

| Magnesium | 1500 - 1790 | 2 | 50 - 76 | 30 - 108 |

| Sulfate | ... | ... | 27 - 110 | 1 -100 |

| Chloride | ... | ... | 90 - 210 | 40 - 139 |

| Phosphate | ... | 759 | ... | 60 - 214 |

| Iron | 32 - 76 | 25 | ... | 0.04 - 0.16 |

| Hardness | ... | ... | ... | 320 - 470 |

| Silica | ... | 112 - 188 | ... | 66 - 182 |

| Source | Boivin, Macleod. 2017 | Salama et al. 1996 | Justus & Schoales, WBC 2020 | Montana State Barley 2021-2022 |

*all values in mg/L -aka- ppm

Common water profiles, brewing targets, and common range found in beer:

| US Tapwater (average) | Pilsen | Burton-on-Trent | Common Targets for Beer | Common Levels Found in Beer | |

| Potassium | 4.9 | ... | ... | ... | 200 - 450 |

| Sodium | 38 | 2-3 | 25-54 | 0 - 150 | 20 - 350 |

| Calcium | 31 | 7 - 10 | 275 - 352 | 50 -150 | 25 -120 |

| Magnesium | 9 | 2-3 | 24 - 40 | 0 - 30 | 50 - 90 |

| Sulfate | ... | 4-8 | 610 - 820 | 50 - 150 | 100 - 430 |

| Chloride | ... | 4-6 | 16 -35 | 0 - 250 | 120 - 500 |

| Phosphate | 0.14 | ... | ... | ... | 170 - 600 |

| Iron | 0.02 | ... | ... | <0.2 | 0.01 - 0.3 |

| Hardness | ... | ... | ... | ... | ... |

| Silica | ... | ... | ... | ... | 46 - 96 |

| Source | Patterson et al. 2013 |

Palmer, 2006 Palmer, 2013 |

Palmer, 2006 Palmer, 2013 |

Palmer, Daniels, Goldammer |

Baxter & Hughes 2001, Briggs et al. 2004 |

*all values in mg/L -aka- ppm

Problem to be Solved:

Currently malt mineral profiles are not reported as the testing is tedious and expensive. Lack of knowledge leaves brewers blind - working with an incomplete equation - when developing their recipes. We at the Montana State Barley program are developing methods to make it possible for maltsters to regularly gain information about their malt mineral profiles!

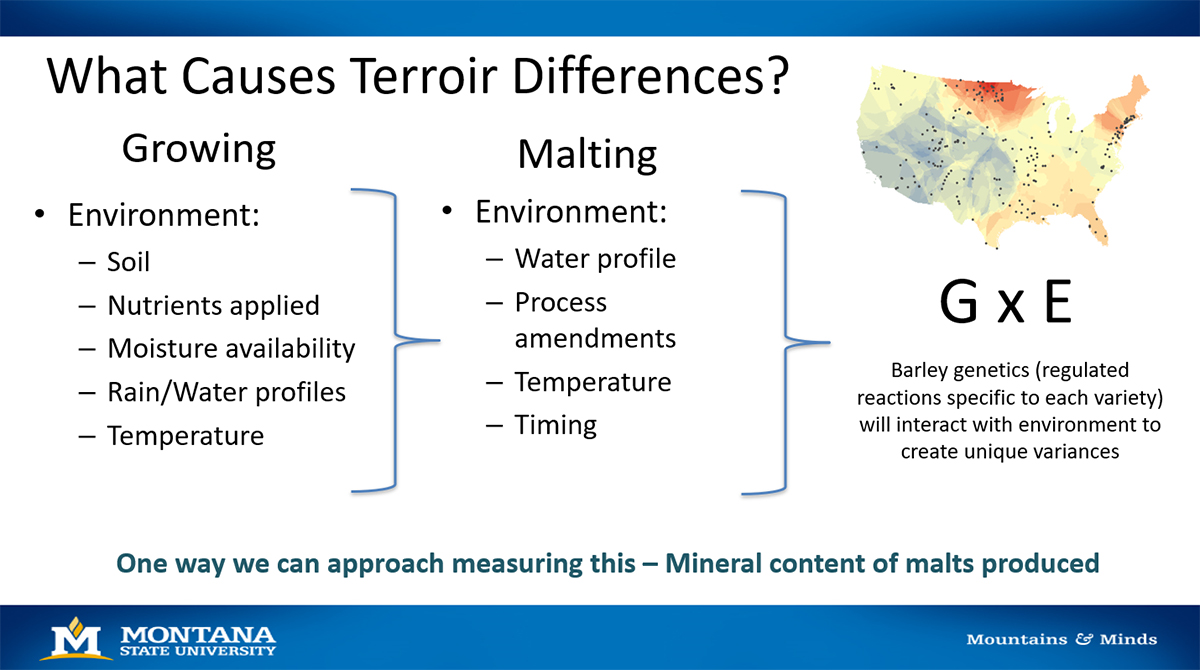

Research is showing that terrior is real for beer -- could ionic minerals help illustrate this finding?

Primary example: why this work is important!

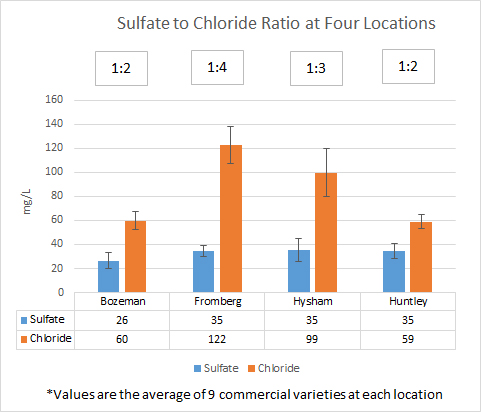

Sulfate to Chloride Ratio

Sulfate: Promotes dry, bitter flavor --> hoppy

Chloride: Promotes sweet, full flavor --> malty

The ratio of these two minerals may be more important to flavor than the actual levels!

Common Targets:

2:1 - for bitter beers

1:2 - for mild ales

1:3 - for stouts and porters

Brewers currently targeting ratios without knowing the malt contributions don't have the full picture!

The table below demonstrates the impact location has on the ratio of sulfate to chloride in malts. Chloride is particularly impacted by location, allowing these malts to range in ratio from 1:2 up to 1:4. A brewer would be fighting the trend to use a Fromberg malt when makinga bitter beer, or could over shoot the chloride need if making stout. Adjustments made on the first brew may change if getting a malt from another location on the second brew.

Barley's grown at four different locations in Montana demonstrate that location can play a huge role in the ratio of sulfate to chloride. With Chloride in particular being impacted, levels can range from 60mg/L to double at 122mg/L in this example.

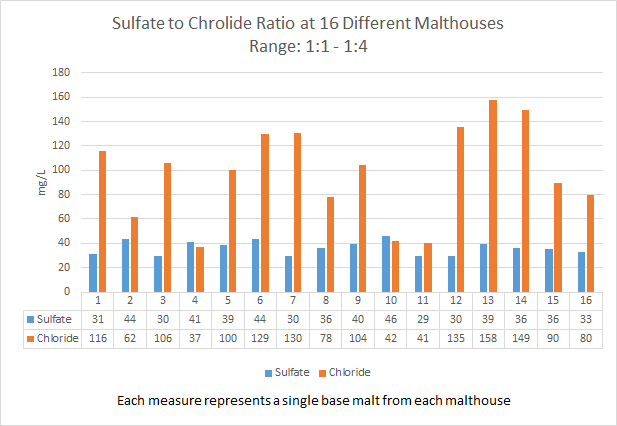

The malthouse also plays an important role in sulfate to chloride ratio:

Malthouses have a unique environment which is layered on top of the growing environment and will have nuanced impacts on mineral composition of a malt, such as sulfate to chrloride ratio.

To continue exploring our early findings follow the links below to learn how

growing environment, malthouse, and barley variety can impact wort mineral profiles!

| Minerals | ||||

| Minerals Impacting Flavor | Sulfate, Chloride, Magnesium, Sodium, Potassium, Iron | Malthouse | Growing Environment | Variety |

| Minerals Impacting Process | Calcium, Phosphate, Silica, Hardness | Growing Environment | Variety |

Learn more, mineral by mineral: Follow the links below for findings specific to each aspect of this research!

| Potassium | Sodium | Chloride | Calcium | Magnesium | Sulfate | Phosphate | Iron | Silica | Hardness |

Page with all figures in one place can be found here

Future Research:

- Mineral characterization of our heirloom malt trial (300+ lines from 47 countries around the world) to gain greater understanding of varietal impact

- Collaboration with malsters to further define "house flavor" and the mineral variations from house to house

- Characterization of mineral profile of malts from MSU fertility trials to determine soil fertility effect

- Pilot scale malting with tailored water profiles to determine the impact of malt water profile

- Further examination of the impact of location on malt mineral profile

- Dialing in our process to make this testing a regular option for malt analysis

Potential Industry Impacts of this Work:

- Brewers empowered to make more informed mineral additions (greater control over final product)

- Improvement of brewhouse performance

- Reduced waste treatment needs

- Defining terroir for malt and beer -- empowering growers and maltsters

- New product development - malts with targeted mineral profiles and malthouses with "house flavor" due to mineral profiles

Contributors:

Hannah Turner, Sarah Olivo, Greg Lutgen, Jamie Sherman - Montana State University

Aaron Justus - Ballast Point

Andy Frame - Bridger Analytical Lab

References:

Baxter, E. Denise, and Paul S. Hughes. Beer: Quality, safety and nutritional aspects. Royal Society of Chemistry, 2001.

Boivin, Patrick and Macleod, Aaron. Advanced Course in Craft Malting. Hartwick University, 2017.

Briggs, Dennis E., et al. Brewing: science and practice. Elsevier, 2004.

Brewers Association. Water and Wastewater: Treatment/Volume Reduction Manual, 2012

Cuzner, Janet. "Colorimetric Determination of Silica in Beer, Wort and Brewing Materials." Proceedings. Annual meeting-American Society of Brewing Chemists. Vol. 27. No. 1. Taylor & Francis, 1969.

Daniels, Ray. Designing great beers: The ultimate guide to brewing classic beer styles. Brewers Publications, 1998.

Goldammer, Ted. The brewers' handbook. Clifton, Virginia: KVP Publishers, 1999.

Justus, Aaron and Schoales, Tyler. Practical Breadkdown of Malt Certificate of Analysis (COAs). World Brewing Congress, 2020.

Kyraleou, Maria, et al. "The Impact of Terroir on the Flavour of Single Malt Whisk (e) y New Make Spirit." Foods 10.2 (2021): 443.

Orr, Katy. Mash and Kettle Salt Analysis: Malt and Barley. Sierra Nevada, 2017

Palmer, John J. How to Brew: Everything you need to know to brew beer right the first time. Brewers Publications, 2006.

Palmer, John, and Colin Kaminski. Water: A comprehensive guide for brewers. Brewers publications, 2013.

Patterson, Kristine Y., Pamela R. Pehrsson, and Charles R. Perry. "The mineral content of tap water in United States households." Journal of food composition and analysis 31.1 (2013): 46-50.

Salama, Abdel‐Razek A., et al. "The chemical composition, the nutritive value and the functional properties of malt sprout and its components (acrospires, rootlets and husks)." Journal of the Science of Food and Agriculture 75.1 (1997): 50-56.